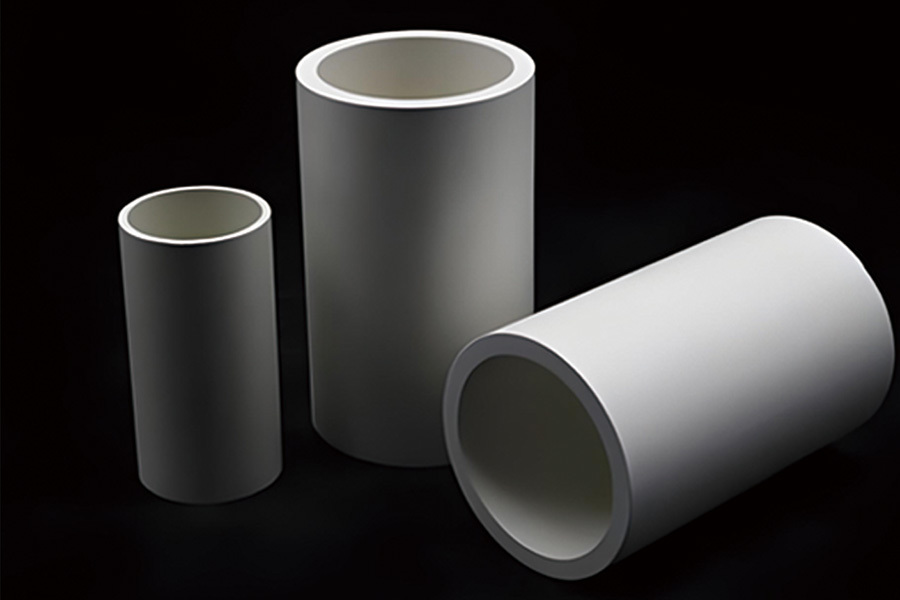

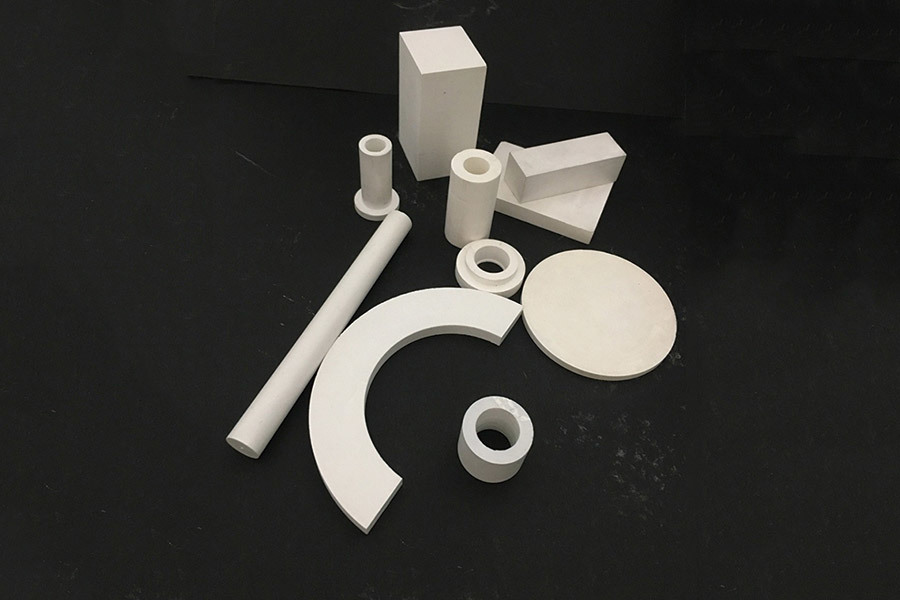

Foviko boron nitride composite ceramic is a high-performance ceramic material made by combining high-purity boron nitride powder with other ceramic materials such as silicon nitride, zirconia, and silicon carbide. It is produced using a hot-press sintering process without the addition of sintering aids, ensuring both high purity and exceptional density.

Application areas

High-temperature industry: Used in crucibles, thermocouple protection tubes, continuous casting separator rings, metal atomization nozzles, and more.

Electronics and Semiconductors: Used as thermal management materials, P-type diffusion sources, microwave windows, and more.

Aerospace: Rocket nozzles, thermal shielding materials for spacecraft.

Nuclear Industry: Neutron-absorbing and Shielding Materials.

Mechanical processing: Wear-resistant components such as high-temperature bearings, valves, and gaskets.

Keywords

Application areas

Additive 3D Printing Industry

Metallurgical industry

Aerospace industry

New Energy Industry

Cosmetics industry

The semiconductor electronics industry

Factory appearance and layout

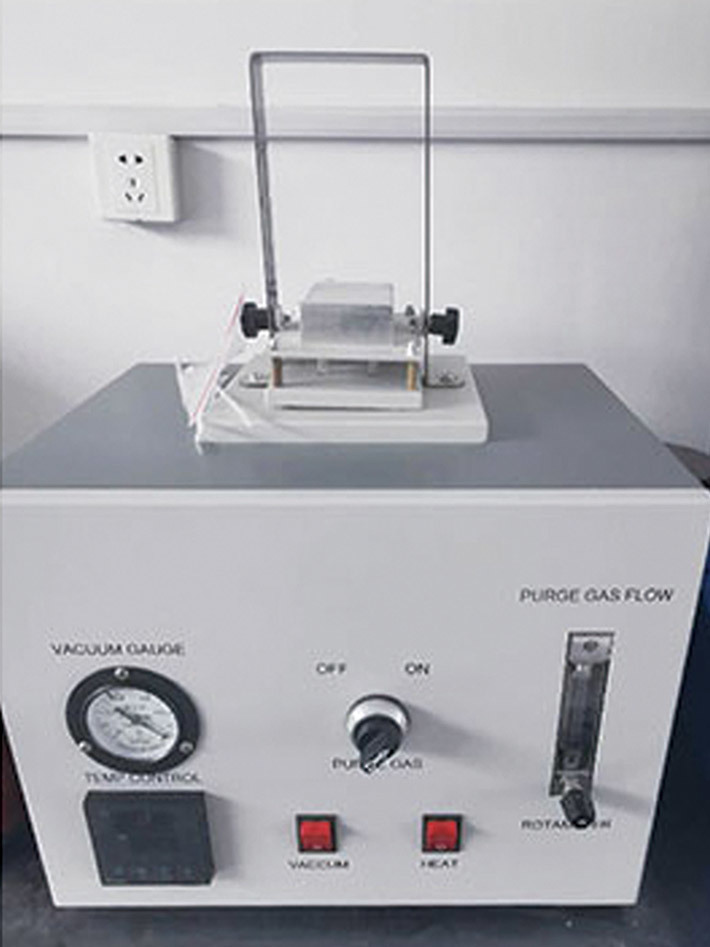

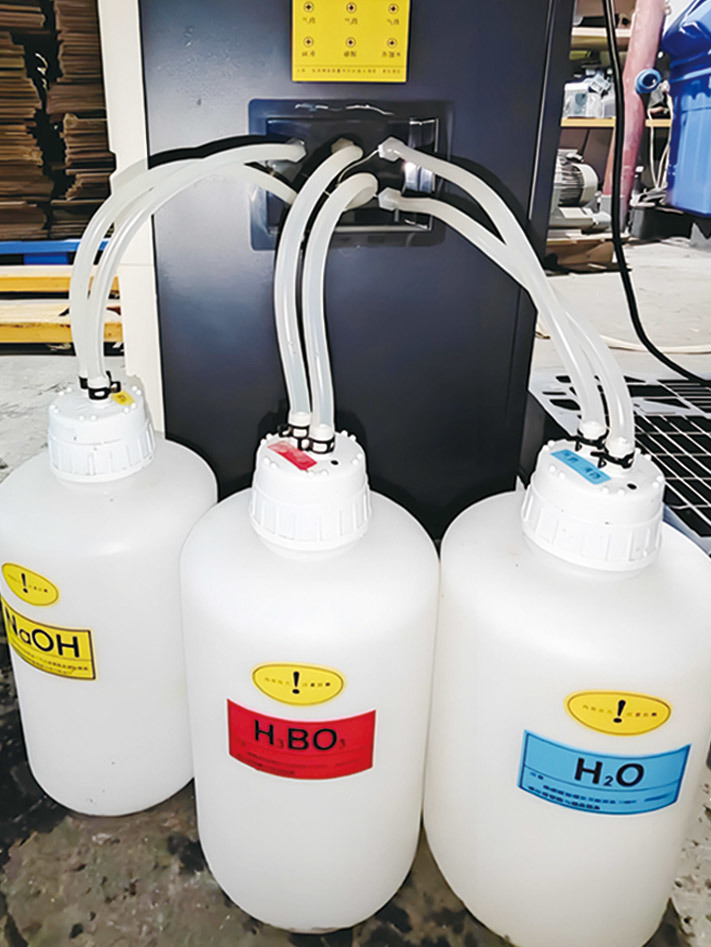

Testing equipment

FAQ

What is the lead time for mass production deliveries?

What are your payment terms?

Can I take a tour of your factory?

Wondering if you accept small orders?

Boron Nitride Composite Ceramic

- Commodity name: Boron Nitride Composite Ceramic

Classification

Consult now

Our professional team is here to serve you.

Related Products

Related Products

Boron nitride ceramic

-

Boron nitride ceramic

The company can provide high-purity or specially formulated boron nitride ceramic products with customized binders, tailored to meet the specific needs of various industries. We also offer comprehensive solutions to support a wide range of application scenarios and custom profile requirements.

-

Boron nitride ceramic

The product boasts exceptional mechanical, chemical, electrical, and thermal properties, making it suitable for a wide range of high-performance industrial applications.

Boron nitride coating

-

Boron nitride coating

Widely used in the demolding processes for metal casting applications such as aluminum, titanium, and copper, as well as in glass thermal bending and optical lens manufacturing.

-

Boron nitride coating

Widely used in the demolding processes for metal casting applications such as aluminum, titanium, and copper, as well as in glass thermal bending and optical lens manufacturing.

-

Boron nitride coating

Increasing product molding yield by more than 20%, reducing mold wear, and extending mold lifespan—while also meeting eco-friendly production standards—is the ideal green solution for modern manufacturing.

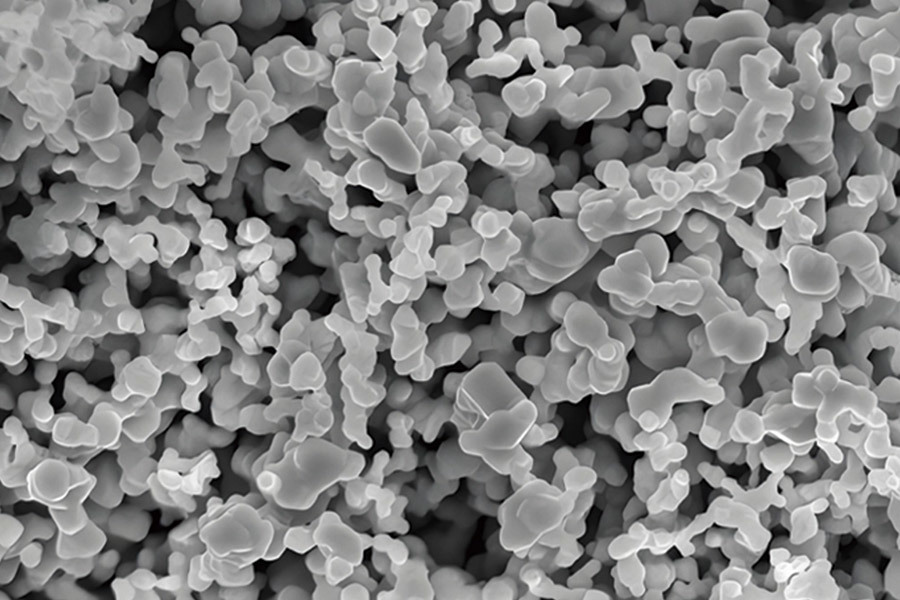

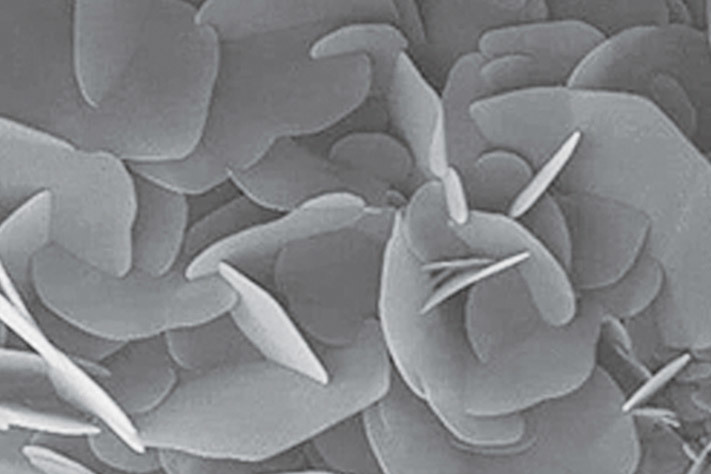

Hexagonal boron nitride powder

-

Hexagonal boron nitride powder

Our company produces boron nitride products using a high-temperature reaction sintering process conducted at 1900°C, ensuring stable chemical and physical properties. Current product offerings include flaky crystalline powders ranging from 2 nm to 100 nm in size.

-

Hexagonal boron nitride powder

Hexagonal boron nitride is widely used in the electronics industry, including applications such as thermal conductive fillers, semiconductor packaging, and LED heat dissipation. Meanwhile, it also demonstrates exceptional performance in traditional industrial sectors like metal smelting, casting, specialty lubricants, and glass manufacturing.

-

Hexagonal boron nitride powder

Hexagonal boron nitride boasts exceptionally unique and outstanding physical and chemical properties, including excellent thermal conductivity, electrical insulation, chemical corrosion resistance, and antioxidant capabilities. It can withstand temperatures up to 1000°C in air, and even higher—up to 2000°C—in inert gases or under vacuum conditions.